The construction industry remains one of the most dangerous workplaces in the United States, with a disproportionately high rate of both fatal and non-fatal injuries. In 2014 alone, 874 construction workers died on the job, accounting for roughly 20% of all workplace fatalities despite construction workers representing only 5% of the U.S. workforce. This alarming statistic underscores a critical need for improved safety management strategies.

The Hidden Cost of Design Flaws

Numerous studies reveal that a significant portion of construction incidents – nearly 42% of fatalities between 1990 and 2003 – stem from decisions made during the design phase, before any construction even begins. This highlights a critical point: safety isn’t just a construction-site issue; it’s fundamentally embedded in the initial design process.

Lean Thinking and the Hierarchy of Controls

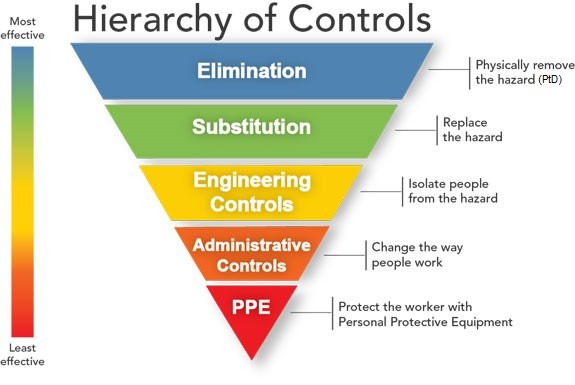

Improving workplace safety isn’t just about avoiding accidents; it’s about eliminating waste and maximizing value. The “hierarchy of controls” (HoC) demonstrates this principle: the most effective safety measures eliminate hazards at their source. This aligns perfectly with lean thinking, which prioritizes streamlining processes to eliminate waste.

Prevention Through Design: A Lean Approach

The most effective way to eliminate construction hazards is through “Prevention Through Design” (PtD) – modifying the facility design before construction to proactively address safety concerns. Lean design practices, such as early involvement of specialty contractors and frequent team communication between design and building professionals, can facilitate this process.

Set-Based Design and Cross-Functional Teams

One powerful lean design tool is “set-based design” (SBD), which involves generating multiple design alternatives upfront and deferring detailed specifications until the optimal solution is identified. This approach, combined with cross-functional teams (CFTs) that bring diverse perspectives to the design process, can lead to superior safety outcomes.

Making Difficult Choices: The Choosing By Advantages Method

Narrowing down multiple design alternatives to a single optimal solution can be challenging. The “Choosing By Advantages” (CBA) decision-making system offers a structured approach to this process, prioritizing advantages between alternatives to ensure the most effective safety solution is selected.

Case Study: Fall Prevention on a Medical Campus

A real-world example demonstrates the practical application of lean design for safety. When designing a rooftop for a utility building on a medical campus in Portland, Oregon, decision-makers considered three fall-prevention measures: a temporary guardrail system, a permanent roof anchor system, and a PtD solution involving a tall parapet around the roof perimeter.

Using CBA, the team determined that the parapet – eliminating the need for fall protection altogether – generated the greatest value by providing permanent, lifecycle-wide safety. This approach not only minimized risk during construction but also eliminated ongoing maintenance concerns.

Conclusion: Integrating Lean Design for a Safer Future

Lean design practices are not merely about efficiency; they are fundamentally linked to improving construction site safety by facilitating proactive design decisions and incorporating prevention strategies into the physical structure of a facility. By embracing lean thinking, the construction industry can move beyond reactive safety measures and create inherently safer work environments, reducing waste, maximizing value, and ultimately protecting the lives of those who build our world